- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

Brand Name : Eternal Bliss

Model Number : EB3120

Certification : ISO9001-2008

Place of Origin : China

MOQ : 50 Kilogram/Kilograms

Price : USD5~16/kg

Payment Terms : by T/T or L/C

Supply Ability : 5000 tons per year

Delivery Time : It depends on the quantity to be ordered.

Packaging Details : Pallets

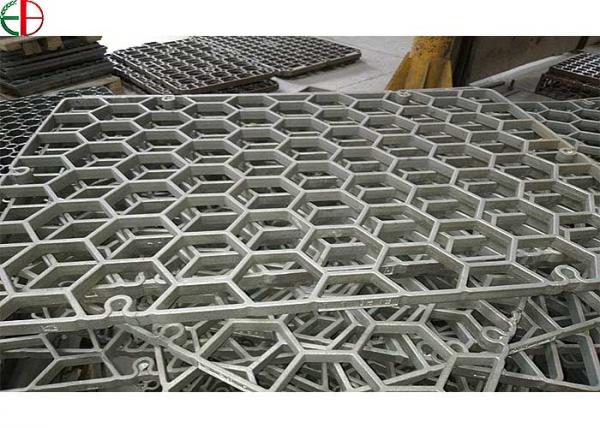

Product Name : Heat-treatment Furnace Wire Mesh Basket

Material Grade : 1.4849

Process : Resin Sand Casting,Centrifugal Cast,Investment Cast

Working temperature : Up to 1300℃

Size : Customized Size

Quality Control : 100% Inspected

1.4849 EPC Process & Sand Process Heat Treatment Casting Base Tray

![]()

Introduction:

We supply finished heat steel parts,such as furnace grates,furnace bed plates for cement works,steel mills.

We can produce heat casting with heat-treated and machined condition if necessary.

Application:Auto,Precision Gear,Heat-treating industries.

Features:

1. Resistance to high temperature:Up to 1300℃;

2. A large number of Existing Patterns of fixture for Standard.Famous Brand Heat-treatment Furnaces.

3. Rich experience in design of Trays&Baskets to suit the secific work condition.

4. More production process available:Wax lost cast process,EPC cast process,Sand cast process.

Quality Level: As per National Standard & International Standards.

Production Process:Wax lost process,investment process,EPC process&sand process.

| GB | DIN | ASTM | JIS | Chemical Composition | Maximum operation | |||||||

| C | Si | Mn | Cr | Ni | Nb/Cb | Mo | Other | |||||

| ZG40Cr27Ni4 | 1.4823 | HD | SCH11 | 0.30-0.50 | ≤2.00 | ≤1.00 | 24.00-28.00 | 4.00-6.00 | – | ≤0.50 | 1050 ℃ | |

| ZG40Cr22Ni10 | 1.4826 | HF | SCH12 | 0.30-0.50 | 1.00-2.50 | ≤2.00 | 19.00-23.00 | 8.00-12.00 | – | ≤0.50 | 950℃ | |

| zG30Cr28N10 | HE | SCH17 | 0.20-0.50 | ≤2.00 | ≤2.00 | 26.00-30.00 | 8.00-11.00 | – | – | 1050℃ | ||

| ZG40Cr25Ni12 | 1.4837 | HH | SCH13 | 0.30-0.50 | 1.00-2.50 | ≤2.00 | 24.00-27.00 | 11.00-14.00 | – | ≤0.50 | 1050℃ | |

| ZG30Cr28Ni16 | HI | SCH18 | 0.20-0.50 | ≤2.00 | ≤2.00 | 26.00-30.00 | 14.00-18.00 | – | – | 1100℃ | ||

| ZG40Cr25Ni20Si2 | 1.4848 | HK | SCH21 | 0.30-0.50 | ≤1.75 | ≤1.50 | 23.00-27.00 | 19.00-22.00 | – | ≤0.50 | 1100℃ | |

| ZG30Cr20Ni25 | HN | SCH19 | 0.20-0.50 | ≤2.00 | ≤2.00 | 19.00-23.00 | 23.00-27.00 | – | – | 1100℃ | ||

| ZG40Cr19Ni39 | 1.4865 | HU | SCH20 | 0.35-0.75 | ≤2.50 | ≤2.00 | 17.00-21.00 | 37.00-41.00 | – | – | 1020℃ | |

| ZG40Cr15Ni35 | 1.4806 | HT | SCH15 | 0.35-0.70 | ≤2.00 | ≤2.00 | 15.00-19.00 | 33.00-37.00 | – | ≤0.50 | 1000℃ | |

| ZG40Cr25Ni35Nb | 1.4852 | HPCb | SCH24Nb | 0.30-0.50 | ≤2.00 | ≤2.00 | 24.00-28.00 | 33.00-37.00 | 0.8-1.8 | ≤0.50 | 1100℃ | |

| ZG40Cr19Ni38Nb | 1.4849 | 0.30-0.50 | 1.00-2.50 | ≤2.00 | 18.00-21.00 | 36.00-39.00 | 1.2-1.8 | ≤0.50 | 1020℃ | |||

| ZG40Cr24Ni24Nb | 1.4855 | 0.30-0.50 | 1.00-2.50 | ≤2.00 | 23.00-25.00 | 23.00-25.00 | 0.8-1.8 | ≤0.50 | 1050℃ | |||

| ZG40Cr25Ni35 | 1.4857 | HP | SCH24 | 0.35-0.50 | 1.00-2.50 | ≤2.00 | 24.00-28.00 | 33.00-37.00 | ≤0.50 | 1100℃ | ||

| ZG1Cr20Ni32Nb | 1.4859 | 0.06-0.15 | 0.50-1.50 | ≤2.00 | 19.00-21.00 | 31.00-33.00 | 0.5-1.5 | ≤0.50 | 1050℃ | |||

| ZG45Cr12Ni60 | HW | 0.35-0.75 | ≤2.00 | ≤2.00 | 10.00-14.00 | 58.00-62.00 | 1100℃ | |||||

| ZG45Cr18Ni66 | 0.35-0.75 | ≤2.00 | ≤2.00 | 15.00-19.00 | 64.00-68.00 | 1100℃ | ||||||

| ZG1Cr28C050 | 2.4778 | HX | 0.05-0.25 | 0.50-1.00 | ≤1.50 | 27.00-30.00 | ≤1.00 | ≤0.50 | ≤0.50 | Co:48.0-52.0 | 1200℃ | |

| ZG30Cr28Co50Nb | 2.4779 | 0.25-0.35 | 0.50-1.50 | 0.50-1.50 | 27.00-29.00 | – | 1.50-2.50 | ≤0.50 | Co:48.0-52.0 | 1200℃ | ||

| ZG40Cr28Ni48W5 | 2.4879 | SCH42 | 0.35-0.55 | 1.00-2.00 | ≤1.50 | 27.00-30.00 | 47.00-50.00 | – | ≤0.50 | W:4.0-5.5 | 1150℃ | |

Product Details:

|

|

1.4849 EPC Process & Sand Process Heat Treatment Casting Base Tray Images |